Following setup requires that all controllers on communication (RS485) line are properly connected and that each controller has unique address and same speed of communication assigned. This means that each automatic controller must have its own address distinctive from other addresses and the speed of communication should be the same on all controllers (Setting automat communication address), which is also same speed as the speed set in the Connecting settings > Baud rate

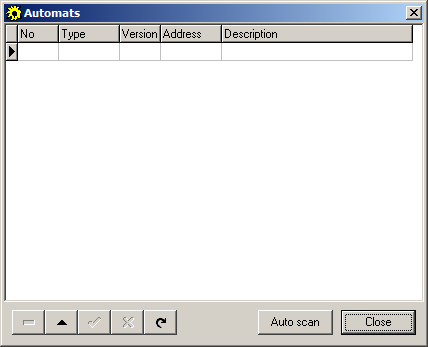

When option Settings> Autimatic controller is selected, following window is displayed:

Click Auto search and wait for DryerManager to try to find any controller on the communications line. If communication addresses and speed are properly set on each controller, software will find all attached devices. During this procedure, transmit LED on RS-485 adapter (Tx) is flashing. When searching process is finished, the window will display all controllers found. They will be listed according to type, version and address. If the search was successful, accept the new configuration, otherwise manual procedure for controller's adding is required.

List of successfully found controllers:

Description names can be changed to better suit each drying facility. This description will be displayed in each controllers display.

After closing the window additional windows for each controller containing all relevant data will show up on screen. Separate window is opened for each controller (drying chamber).

Every setting is remembered so next time DryerManager is started all controllers will be loaded without searching.

When DryerManager is started, LEDs on RS485 adapter which indicate transmitting and receiving will flash. Flashing indicate normal response from controllers. If flashing of receiving LED (Rx) stop, then controllers are turned off, or communication cable is damaged. If transmission LED (Tx) does not flash also, then wrong COM port for communication is selected or RS adapter itself is malfunctioning.