Automatic control unit MC-502R

is a device that automatically controls drying process in

small conventional kilns. It can also be used in bigger

conventional dryers as a cheeper option for automatic controllers

MC-600

and

MC-2000.

This

device is based on older automatic control unit

MC-500R

which is modified to further improve drying process in

conventional dryers. This regards above all on adding the

relay output for fans direction reversion. Also, buttons for

starting and stopping of the drying process are added. Device

alone is now placed in plastic box suitable for wall mounting

which makes installation process much easier. Further more, a

newest concept of temperature, EMC and wood MC data aquisition

is applied. MC-502R standard configuration includes

measurement box DS-04 attached to measurement module

MM-04

which transfers data to MC-502R. These boxes are

interconnected using LIYCY 10x0.34 cable which is provided and

delivered by "NIGOS" with the rest of equipment. This

way, the nuber of cables used for installation is greatly

reduced and the control unit itself can be placed on greater

distance than before (up to 30 m).

Aditional advantage of this device is its low price, so it is

ideal for low-cost dryers (NKS).

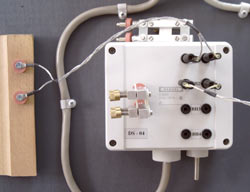

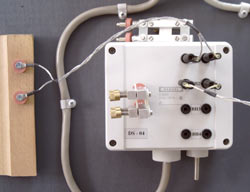

Pictures on the right show connection of MC-502R with

MM-04

and DS-04 boxes, as well as enlarged picture of

DS-04

box with fitted probes.

|

|

|

|

MC-502R achieves optimum conditions for wood

drying inside the chamber through air temperature and humidity control.

MC-502R controls its relay outputs automatically, semi-automatically

or user can do it manually based on data obtained from temperature and

EMC probes (in 1 point) and wood MC probes (obtained from 4 points). In

addition, control of drying process is adjusted according to user

settings.

In automatic operation mode, MC-502R follows

chosen drying schedule (regime). There are 20 invariable (built-in)

schedules which are inserted in unit's memory by "NIGOS" during production and which can not be changed.

In semi-automatic operation mode user set the

desired values for temperature and EMC based on personal experience and

measured wood MC and automatic control unit MC-502R only maintain

this values inside the chamber.

In manual operation mode, buttons and switches

on the right side of device are used. Switches give the user an ability

to choose manual control of heating valve, servo-controlled flaps and

valve for spraying. Button is used for change (reversion) of fans

direction. While in manual operation mode, MC-502R only displays

measured values for T, EMC and MC, but it has no influence on the relay

outputs and equipment inside the chamber. User himself must control

temperature and humidity by pressing the appropriate buttons.

After power failure, if it was started, drying will

automatically continue when power is reconnected starting from measured

wood MC.

Automatic control unit is delivered with following

equipment included (standard configuration):

- Automatic control unit MC-502R: 1 pcs

- Measurement module MM-01: 1 pcs

- Measurement box DS-04 with fitted temperature probes: 1 pcs

- EMC paper holder which is fitted on DS-04 box: 1 pcs

- EMC paper in quantity sufficient for 2 years drying: 1 set

- Set of wood MC probes for different wood thickness: 1 set

- Cables for boxes connection: 12m

- Tephlone cables for wood MC measurement: 8m x 4 pcs

Warranty for automatic control unit MC-502R

is 5 years.

Technical data of MC-502R are given in the following

tables:

|