|

|

|

- Completely automated

- Drying of all types of wood regardless of the starting moisture content

- Minimal energy consumption:

max 100 kWh per m3 of timber for entire drying cycle

- Can operate on spare power sources

- Maximal working temperature 65 °C

- Environment friendly

|

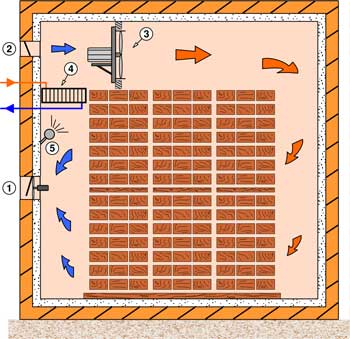

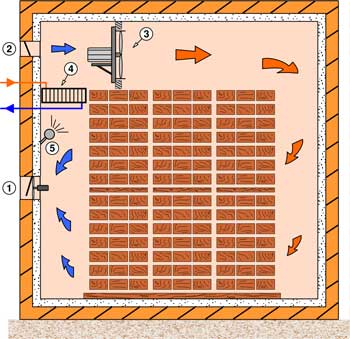

Mini kiln scheme:

-

Exhaust flaps

- Intake flaps

- Circulation fans

- Heaters

- Atomizers

|

These are the kilns that ensure high drying quality of all wood types with the least energy consumption (up to 100 kWh per m3

of timber for entire drying cycle). Air circulates in one direction only at the velocity of up to 1,5 m/s. This ensures equal

drying of timber of up to

4 m. Installed power of fans is approximately 0,15 kW per m3 of timber. Depending on user

demand, MC-412,

MC-502R or

MC-600

automatic control unit can be mounted.

These kilns are especially convenient wherever some electrical power supply problems may

occur, because they can operate on spare power sources.

Technical data

| Model |

Timber

volume

(m3) |

Heating

power

(kW) |

Flow

fans |

Electrical

power

cca(kW) |

Optimal

dimensions

of

chamber

(axbxh)(m) |

Available for timber

stacking

(axbxh)(m) |

| NKS-06 |

5 to 8 |

24 |

2 x Ø560 |

1.5 |

6.0x2.4x2.4 |

4.5x1.6x2.1 |

| NKS-12 |

8 to 15 |

40 |

4 x Ø450 |

1.6 |

4.6x4.5x3.0 |

4.5x3.5x2.4 |

| NKS-20 |

15 to 25 |

80 |

4 x Ø560 |

3.0 |

4.6x6.2x3.8 |

4.5x5.0x3.2 |

|