|

|

|

- Heat pump - the heart of a drying kiln

- Completely automated

- Drying of all types of wood regardless of the starting moisture content

- Communication

- Minimal energy consumption:

100 - 250 kWh per m3

of timber for entire drying cycle

- Installed power 1kW per m3 of timber

- Maximal working temperature 60 °C

- Exceptional quality of drying

- Best quality of natural (untreated) wood

- Environment friendly

|

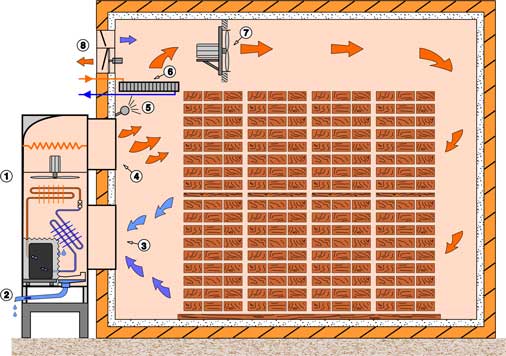

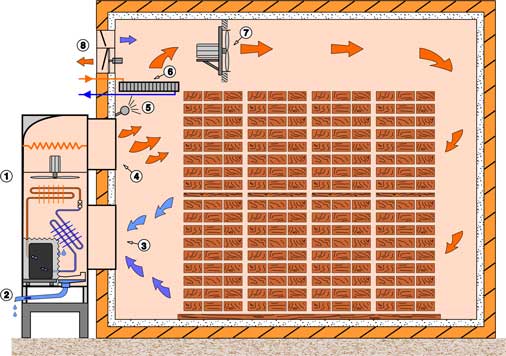

Dehumidifying kiln

scheme:

- Heat pump

- Drain pipe

- Openings for absorbing of cold and moist air from the chamber into the heat

pump

- Openings for insufflating of warm and dry air from the heat pump into the

chamber

- Humidifying system (atomizers)

- Heat exchanger (in combined kilns only)

- Flow fans

- Air exchange system (intake and exhaust flaps)

|

Wood dryers:

Conventional kilns

Dehumidifying dryers

Mini (Low-cost) kilns (NKS)

Heat pumps

Additional equipment

Power electric switch board

Catalogues and manuals:

Wood dryer catalogue (.pdf 3.7MB)

NIGOS dryers (.pdf

956KB)

User manuals

Measurement&controll

equipment catalogue (.pdf 2.8MB) |

Automatic controllers for wood drying:

MC-411R, MC-412,

MC-504,

MC-600, MC-904,

MC-2000

Automation of existent conventional kilns

Archive (obsolete products no longer produced):

(MC-100RM, MC-500R,

MC-502R, MC-900R,

MC-100R, MC-1000)

| MC-502R |

(Obsolete!

This model is no longer produced!)

Wood MC meters:

Portable moisture meter RVD-904

Nondestructive moisture meter DVD-240

Other:

Control unit for

steaming chambers PD-02

ISPM-15 wood

pallet sterilization unit MKS-05

|

Dehumidifying kilns belong to newer wood drying technologies.

These kilns are also called condensing wood dryers (drying kilns). Condensation of water (dehumidification) is used for separating moisture from

wood, without external air exchange. Our kilns are completely automated, which

means that with the equipment, user also receives a wood drying technology.

Kiln can be constructed or assembled of aluminum bearing structure.

Most important part of a dehumidifying kiln is a

heat pump. Air in the kiln passes through the load of timber and absorbs

moisture from the wood. Part of that air circulates through the heat pump where

the moisture is condensed and drained out of the chamber. Dried, reheated air

comes back to kiln chamber. Energy consumption is minimal, since there is almost

no inner/outer air exchange. Air circulation in these kilns is smaller than in

conventional kilns while the electrical power of flow fans and heat pump

equals approximately the power of flow fans in

conventional kilns.

Automatic control unit especially designed in "NIGOS-elektronik"

controls drying process.

Automatic control unit has built-in programs for

drying of all wood types regardless of a starting wood moisture content. It

controls drying process automatically, so the operator presence is not needed

during drying.

User have an ability to connect up to 15 kilns to a single PC computer, and

control the drying process from a distant place (office or some convenient room)

up to 1000 m away.

Average energy consumption is approximately 30% - 60% of installed power,

which is up to 1kW per m3 of timber

(as shown in technical data tables below). If we monitor the whole drying cycle,

energy consumption is about 100 - 200kWh per m3

for the whole drying cycle.

Larger energy consumption is only during first

day during heating stage when electrical heaters are turned on until

working temperature is reached. Later, during drying stage these heaters

are rarely turn on.

If a boiler installation exists in the drying complex, it

makes sense to mount heat exchangers for hot

water or steam (depending on the boiler) in the kiln. In that case, energy from

the boiler would be used for heating of the drying chamber. That way kiln

becomes combined (automatically uses boiler heat). This option is

interesting only for a large capacity kilns and in the cases where electrical

power supply is unstable (large voltage or current oscillation or frequent power

cut-downs during winter periods). Drying is in that case performed in

conventional way, heat pump is turned-off, and electrical energy is used only

for flow fans. Combined kiln unites good characteristics of both dehumidifying

and conventional kiln. That provides the

greatest drying quality with the least energy consumption for the shortest time.

Drying quality in dehumidifying kilns

is significantly better than in any conventional kiln, because the drying is

equable in whole timber load, so there is no danger of developing degrade in the

timber (cracks, checks, warping...). drying is fast enough since the working

temperature can reach up 60 0C to. These kilns are environment

friendly because all wastes that are produced during drying process are harmless

for water and environment.

Especially good results are achieved with

drying of natural (untreated) wood (beech, ash,...).

"NIGOS - elektronik" gives its

customers 1 year warranty for whole kiln and heat pumps, and 5 years

for the automatic control unit.

Approximate time of drying

Type of

wood |

Drying in days from 70% to 10% and from 40% to 10%

of wood

moisture content for various timber thickness |

|

25mm |

38mm |

50mm |

70mm |

from 70%

to 10% |

from 40%

to 10% |

from 70%

to 10% |

from 40%

to 10% |

from 70%

to 10% |

from 40%

to 10% |

from 70%

to 10% |

from 40%

to 10% |

|

Oak |

20 |

13 |

35 |

22 |

52 |

32 |

75 |

52 |

|

Ash |

15 |

10 |

25 |

15 |

38 |

24 |

60 |

42 |

|

Beech |

10 |

7 |

16 |

11 |

25 |

16 |

41 |

28 |

|

Birch, poplar |

6* |

4* |

11 |

8 |

14 |

10 |

21 |

14 |

|

Pine, fir, juniper |

6* |

4* |

9 |

7 |

12 |

9 |

18 |

13 |

Comment: Times marked with * can be achieved

in combined kilns only.

Technical data

| Model |

Capacity

range

(m3) |

Heat

pumps |

Flow fans

power

(kW) |

Inst.

power

cca(kW) |

Average

consumption

cca(kWh) |

Optimal

dimensions

of chamber

(axbxh)(m) |

| NIGOLUX-12 |

8 - 15 |

1xTP-15 |

1.6 |

10 |

4 |

4.6x4.5x3.0 |

| NIGOLUX-20 |

15 - 25 |

1xTP-25 |

3.0 |

18 |

8 |

4.6x6.2x3.8 |

| NIGOLUX-30 |

25 - 35 |

1xTP-30 |

6.0 |

24 |

11 |

4.6x6.5x5.2 |

| NIGOLUX-40 |

30 - 50 |

TP-15 + TP-25 |

9.0 |

36 |

16 |

6.8x7.0x5.2 |

| NIGOLUX-60 |

50 - 70 |

2xTP-25 |

12.0 |

48 |

22 |

8.6x7.0x5.2 |

| NIGOLUX-80 |

70 - 100 |

3xTP-25 |

13.5 |

70 |

32 |

8.6x8.2x5.2 |

|