|

Serbian version

Russian version

Wood dryers (drying kilns)

catalogue (.PDF 4MB)

Measurement & control equipment

catalogue (.PDF 2.8MB)

|

|

|

|

|

|

ADDITIONAL EQUIPMENT |

|

|

NIGOS-elektronik is

manufacturer of all additional equipment for wood dryers beside electronic

equipment for measurement and control of the ambient conditions in the kiln.

That way, our customers get everything they need to start drying the wood

imidiatelly. This equipment is mainly manufactured and assambled by "NIGOS", or

in some cases parts are purchased from the world leading manufacturers and then

assembled by "NIGOS". "NIGOS" gives its customers 1 year warrenty for entire

kiln and kiln's equipment and 5 years warrenty for automatic control units used

in it.

|

|

|

|

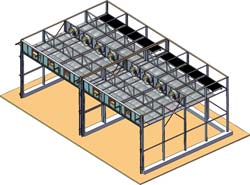

Kiln chamber can be constructed

of concrete or bricks by user, or assembled of aluminium bearing structure

provided by "NIGOS". The walls and the roof, as well as the kiln doors are made

of insulated aluminium coated panels with foamed polyuretane. Rubber gaskets are

put on the both side of the doorframe to ensure the total sealing. The main door

can be winging or sliding with special mechanism for opening and closing. Every

kiln is provided with an inspection door. |

|

|

Air circulation is provided by

flow fans placed under the ceiling. Flow fans are mounted on the aluminium "L"

bearing structure, while the empty spaces between them are closed with aluminium

plates. Axial fans with aluminium structure are used. Propelers are made of

polyamid and strenghtened with glass-fibre. Engine is tropicalized (resistent to

increased humidity and temperature). Fans can be mono-directional or

bi-directional (reversible), depending on the type of dryer. |

|

|

Air exchange system in the

dryers with mono-directional air circulation consist of flaps with fans and

automated shades. In dryers with bi-directional air exchange servo-controled

dampers (flaps) are used. In both cases dampers are made of aluminium plates and

can provide a homogeneous air exchange. |

|

|

Heat recovery units can be

mounted on conventional wood dryers (kilns). Great impact on environment

preservation is possible with minimum investments. These HR units can save more

than 30% of heating energy (and consequenly fuel for boiler), reduce drying time

and improve quality of drying. Heat recovery units are installed on the back of

the kiln instead of standard air exchange system with dampers. |

|

|

Production of cold steam (spraying) using high presure

provide quality moisturizing of a timber during drying process.

Humidifying system consist of water pump, filter, valve and sprinklers. |

|

|

Bimetalic heat exchangers are

made of quality stainless steel (INOX) finned tubes. Finning is made of

aluminium fins. This ensures good heat transfer and long exploatation in harsh

conditions inside drying chamber. Working medium can be hot water or steam. |

|

|

Stainless steel electrodes

(wood MC probes) fitted in wood constantly measure wood moisture content (MC),

while precise probes that do not need special maintenance during drying process

measure temperature and equilibrium moisture content

(EMC). Automatic control units use this measured values to control drying

process. |

|

Wood dryers:

Conventional kilns

Dehumidifying dryers

Mini (Low-cost) kilns (NKS)

Heat pumps

Additional equipment

Power electric switch board

Catalogues and manuals:

Wood dryer catalogue (.pdf 3.7MB)

NIGOS dryers (.pdf 956KB)

User manuals

Measurement&controll equipment catalogue (.pdf 2.8MB) |

Automatic controllers for wood drying:

MC-411R, MC-412,

MC-504, MC-600,

MC-904,

MC-2000

Automation of existent conventional kilns

Archive (obsolete products no longer produced):

(MC-100RM,

MC-100R,

MC-500R,

MC-502R,

MC-900R,

MC-1000)

Wood MC meters:

Portable moisture meter RVD-904

Nondestructive moisture meter DVD-241

Nondestructive moisture meter MCD-50

Other:

Control unit for

steaming chambers PD-02

ISPM-15 wood

pallet sterilization unit MKS-05

|

|